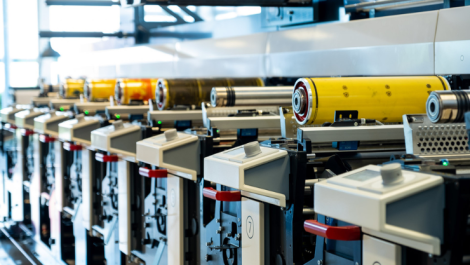

Leicestershire-based label printer Advance Labels has installed a second Proflex 330 flexographic press from UK manufacturer Focus Label Machinery. The investment is aimed at increasing production capacity and expanding the company’s capabilities in medium to high-volume label production.

The new press complements an existing Proflex 330 already in operation at Advance Labels. Designed for flexible, high-speed production, the Proflex 330 features a modular build, allowing for future upgrades and a variety of configurations to suit different applications, explained Focus.

Advance Labels’ managing director, David Gregory, said the installation supports the company’s ongoing growth, which has averaged 20% annually over the past three years. He also highlighted the company’s strong staff retention and focus on quality, noting that Advance Labels has achieved AA-grade BRC audit ratings for the past two years.

“The Proflex is straightforward to operate, and we had it running at full production just days after delivery,” said Mr Gregory. “Focus has been a reliable partner for us, and we value the opportunity to support UK manufacturing by continuing to invest in British-made equipment.”

Focus Label Machinery’s head of sales, James Thomas, noted the long-standing relationship with Advance Labels and emphasised the press’s versatility for narrow web printing. “The Proflex 330 is a practical solution for printers needing modularity, speed, and consistent quality,” he said.

The Proflex range includes servo and line shaft models, fast-change cylinder systems, and a variety of drying technologies including IR, UV, and LED UV. Focus also manufactures a 250mm-wide version and offers solutions for unsupported films, cartons, and other specialist substrates.

In addition to flexographic equipment, Focus supplies hybrid and digital presses, as well as finishing solutions for the narrow web printing market.