Bobst has announced a series of events which will take place between 7 – 15 October 2025, coinciding with the K 2025 trade show, which takes place in Düsseldorf at the same time. The events will highlight the company’s range of new solutions and services to help customers in the flexible packaging industry.

The company plans four events: the Bobst Manchester Open House on the 7 October, which will premiere the company’s newest metallizing technology; Bobst San Giorgio demo on demand from the 8 – 15 October, which will demonstrate Bobst’s development of smartGravure; and Bobst Bielefeld special summit on the 9 and 14 October, which will showcase a full end-to-end production workflow of CI flexo with the latest enhancements.

The last event, a VIP interactive breakfast event at Bobst Meerbusch on the 9, 10,12 and 14 October, will explore solutions and real-world examples alongside its solutions partner Co-ëfficiënt, a consultancy firm specialising in sustainability and operational efficiency in printed packaging. This event takes place 15 minutes from Messe Düsseldorf where the K show is held. Alternatively, attendees at K 2025 can arrange to meet with a Bobst expert at one of the booths of the company’s strategic partners at the show.

“Our event schedule during K 2025 provides something for everyone, with a series of events that will suit individual customer needs and allow them to see our solutions first-hand and explore their own situations and opportunities with our experts,” said Christian Zeller, head of marketing for the printing and converting business unit at Bobst.

The company has also outlined what new services and solutions it will reveal during this period. Bobst’s consulting service, Application Management – launched in 2023 – will be improved. The company said a new application will be available in Application Management for polyethylene (PE) and paper streams. This will help customers to implement a process to produce PE-based or paper-based recycle-ready ultra-high or high barrier packaging.

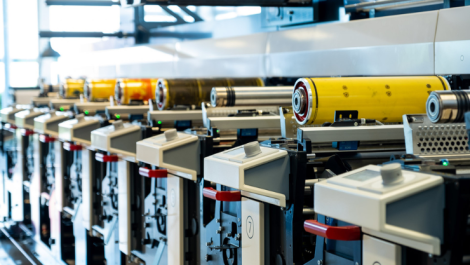

Bobst Connect will receive a new feature. The Data Kit in Bobst Connect will get additional sensors and/or PLC communication to ensure non-intrusive data acquisition. This will enable real-time monitoring and analysis of machine performance.

The company said the innovations that support customers along the flexible packaging production line will be shown. These include its water-based ink printing technology, smartGPS, and oneECG, which enables colour consistency and repeatability. The company said oneECG is flexible across substrates and has an output increase compared to traditional CMYK + spot printing. This solution is retrofittable on installed machines.

“Our customers are seeking to improve production efficiency with reduced downtime and waste, all while ensuring premium print quality,” commented Mr Zeller. “At the same time, many of them are looking to shift their packaging portfolio to recycle-ready solutions and accelerate time-to-market.” He added that Bobst can provide all this with “best-in-class” equipment for every stage of the end-to-end value chain to help customers reach their full potential.