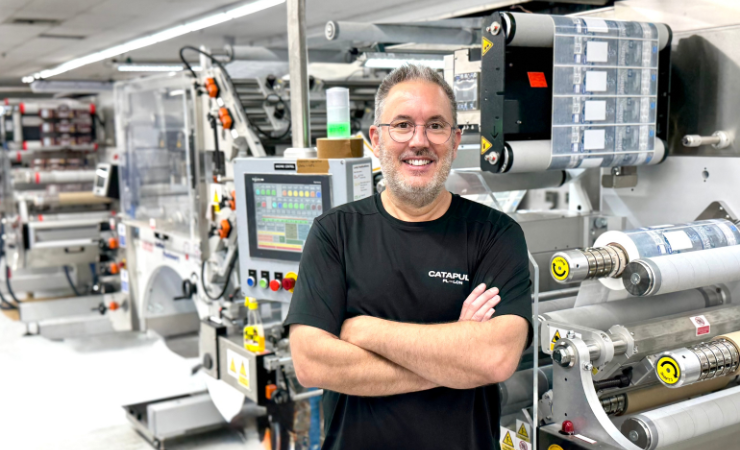

US label printer Catapult Print has appointed former Ravenwood engineer Darren Wardman as the company’s first technical operations engineer. The company claims it is the first US label printer to appoint a full-time in-house engineer.

Mr Wardman brings more than 20 years’ experience at Ravenwood to his new role. In this position he will provide a US-based field engineering service for Catapult customers as well as servicing and maintenance on all of Catapult’s machinery and equipment to minimise the risk of unplanned downtime and optimise efficiency. He will also oversee installation, and commissioning of any new machinery at Catapult’s Florida plant.

According to the company it has the largest coater capacity of any label printing business in the country. The company has eight Nilpeter FA-Line presses, including the first ever Nilpeter 26in web width FA-Line press.

Mark Cook, co-founder and chairman of Catapult, said Mr Wardman’s appointment is part of the company’s goal to drive quality, efficiency and reliability, and to be a true partner for its customers. He added: “We have a team of specialists here at Catapult, along with efficient, modern equipment and state-of-the-art automation and data-driven processes, but Darren has unmatched linerless printing equipment knowledge and will be a huge asset to both our team and our customers.”

Mr Wardman’s appointment is the latest move in Catapult’s approach to adding value-driven services to its print business model. The company said it already offers short lead times, thanks to automation and real-time data, and has recently added the Crystal+ app to its customer dashboard, enabling customers to access real-time data and order stock from their cell phone or handheld device.

“It’s exciting to join a company that is constantly considering new ways to make life easier for the customer and leverage both knowledge and technology to add value,” commented Mr Wardman. “I have visited Ravenwood customers across the USA, Canada and South America throughout my career to provide maintenance and repairs for their equipment and I am looking forward to providing the same service for Catapult’s customers, while also building my familiarity of other machines to help both Catapult and our customers optimise efficiency and remain agile.”