Sandon Global believes new investments made in plasma coating technology at its UK headquarters will prove to be a ‘game changer’ for the anilox manufacturer, enabling it to target wide web markets.

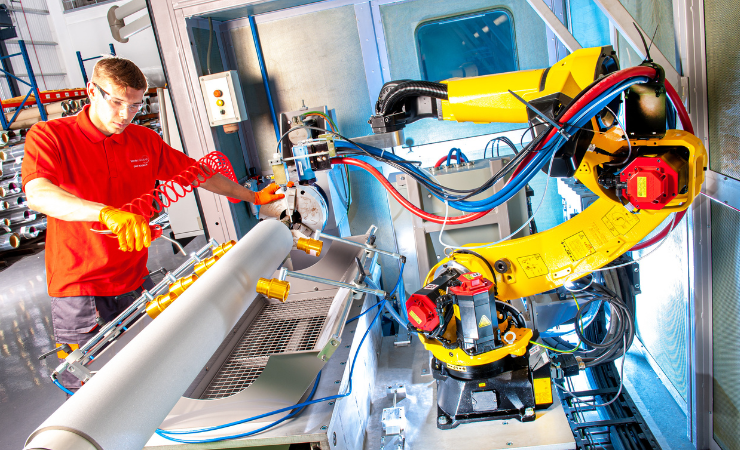

The two new plasma coating booths use proprietary thermal spray technology which Sandon claims will allow it to achieve increased hardness and lower porosity than competing products. For printers, this will mean reduced waste and cost and premium quality print performance, the company said.

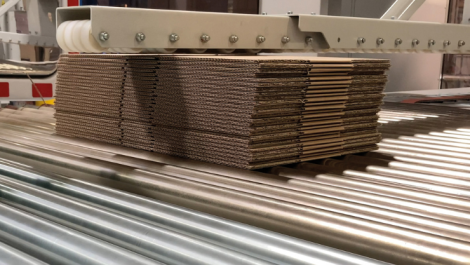

Critically, the plasma coating technology provides six-metre capability, which makes it possible for Sandon to tap into wide-web applications such as tissue, toilet roll, non-wovens, corrugated and textiles markets.

The company’s purpose-built headquarters in Runcorn already includes research and development facilities that Sandon describes as state-of-the-art, including an in-house metallurgical laboratory, and a powder manufacturing line that allows it to maximise anilox performance through developing its own powder coating formulations.

Richard Millington, managing director of Sandon Global, said the business is ‘investing in the future of anilox’. He said, ‘We never stand still and have made significant progress since the move to our new headquarters with our unique R&D facilities. We’re focused on delivering next generation anilox solutions for a wide range of customers around the world and these latest capabilities change the game for us in terms of product performance and market access. We’re really excited about the progress we can now make in untapped markets.’