Morancé Soudure France has purchased an F2 MC 10-colour flexo press from Comexi to produce flexible packaging for food, pet foods, frozen foods and garden centres.

‘We have decided to invest in a Comexi F2 MC 10-color press for various reasons. First, to renew our fleet of flexographic machines. We had two old machines from another company; the Comexi F2 MC 10-color will largely replace the production of both these machines. Second, we were looking for a flexo machine with extremely short set-up times, in order to reduce our costs due to the ability to change multiple SKUs. Furthermore, the re-print system is a huge asset, and this will be our first 10-colour flexographic press,’ explained Olivier Fedel, CEO of Morancé Soudure France.

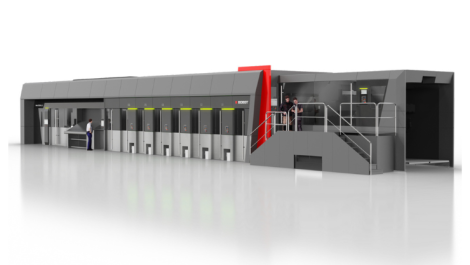

The Comexi F2 MC press has been designed to minimise impacts and vibrations, and allows converters to achieve excessive speeds without bouncing. The new drying system reduces the required energy, while ensuring a perfect drying of the substrate. Inking and doctoring, which are considered the core of flexographic printing presses, have been optimised through three different patents regarding the design of the inking system and doctor blades. The collaboration with top suppliers of video and inspection systems creates a complete automatic pressure and register set up system with minimum waste.

The acquisition of the Comexi F2 MC 10-colour is an additional purchase to a Comexi S1 DT slitter, which the French company acquired in 2020. ‘We are extremely satisfied with our slitter. It has enabled us to optimise the productivity of our flexographic projects, as we no longer use the process of inline die-cutting with our printing machines,’ affirmed Olivier Fedel.