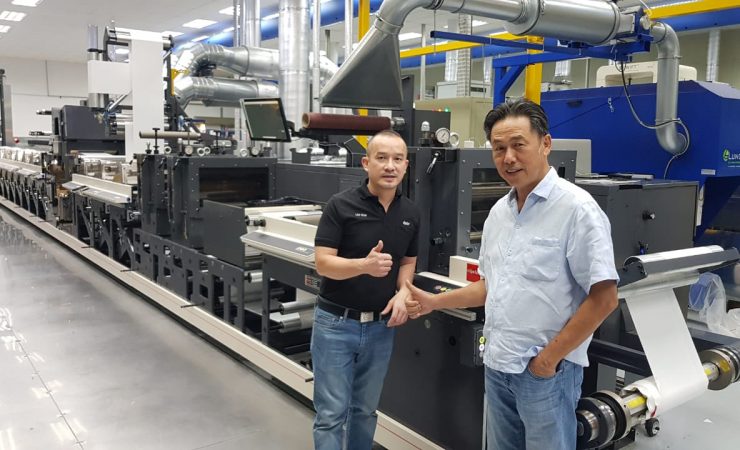

Indonesian printing company, Master Label, has acquired a 22’’ Nilpeter FA-Line with 12 UV-flexo printing units, gravure, and cold foil, making it the largest Nilpeter flexo press in the country.

The modular, multi-substrate 22’’ FA-Line provides a high level of stability, the tight register tolerance, and can print on multiple substrates; all normal self-adhesive materials, including flexible packaging films, polymer films, metallic films, and paper. According to the company, the FA-Line’s open frame provides easy access for quick job setups and changeovers.

Dharmadi Bongso, owner of Master Label, said, ‘The new investment will take Master Label to a new level through higher production efficiency and printing quality. The new FA-22 is configured to a degree where we can meet all demands from the market, while also exploring new opportunities. Since installation, we’ve run shrink sleeves, PE-material, tobacco, and long-run label jobs, benefitting from the fast changeovers, easy setup, and extremely good material handling. The press has a technical specification, which enables us to cater to the label printing market as well as the flexible packaging market, which continues to grow in Indonesia.’

Master Label supplies health & beauty labels for all high-end brand owners in the region, in addition to labels and flexible packaging products in food & beverage, household care, pharmaceuticals, special chemicals, specialty and smart packaging.

The FA-Line was delivered to at the height of the COVID-19 pandemic, making this a very challenging installation. Nevertheless, the respective teams worked tirelessly to complete the task, adhering to all social distancing guidelines.