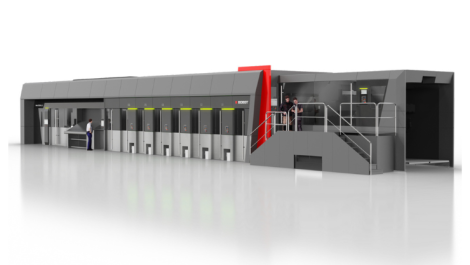

Koenig & Bauer has launched a new sheetfed flexo press, the CorruCUT, designed for short makeready times with the corrugated board market.

The CorruCUT incorporates a vacuum-belt feeder without infeed roller, a new solution for anilox roller exchange, and an overhead vacuum delivery. The CorruCUT handles corrugated sheets with a width of up to 110 inches and a thickness of 0.354 inches, running at speeds up to 12,000sph using DriveTronic shaftless drives. It allows operators to set up while production is running and allowing fast job change overs. It provides operators with integrated error diagnostics and online remote maintenance. Users control the machine with a flexible Profibus system and touchscreen. Its open-architecture design permits access to the printing units for setup while the current production continues. Its production management system can save repeat jobs and the automatic presetting of job parameters.

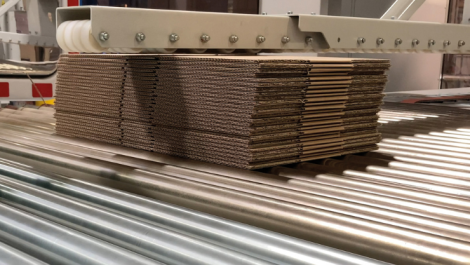

Sheets are carried in register from the feeder, via the printing units to the rotary die-cutter by way of a continuous overhead vacuum transport system. The direct drive technology also allows the use of different printing plate thicknesses by compensating the circumferential speed of the cylinder. The low volume of the chamber blade helps to reduce ink losses. The ink supply and the automatic washing system combine low water consumption with fast washing times.

‘Corrugated customers are seeking machines with faster setup and more automation as well as tailor-made solutions for their specific environment,’ said Jeff Dietz, vice president of the Web & Speciality Press Division at Koenig & Bauer (US). ‘Waste handling in the corrugated process is a big concern as is colour consistency and repeatability for brands. We believe the new CorruCUT will satisfy the needs of printers who require high graphic corrugated printing and converting machines that are faster and more cost efficient to operate. Our CorruCUT flexo press will enable us to further consolidate our strong position in the growing packaging market.’

The Klingele Group is the first customer to install the new press with an integrated high board line rotary die-cutter at its German box plant. Working in partnership with Klingele, the new press has been designed for the high-performance rotary production of die-cut corrugated products in ultimate flexo post-printing quality. The Klingele six-colour press is a completely new design – from the feeder, via the printing units and rotary die-cutter to the delivery.