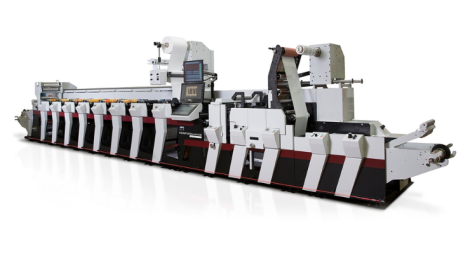

This Roland printer is part of the new mock up packaging system at R3.

To grow its mock up services division, Reproflex 3 has invested in new software and printing capabilities.

The company has purchased an Oris Flex System with a Roland VersaCAMM VSI 300 inkjet printer with XG inks, and a Roland VersaUV LEF300 UV inkjet printer from Oris Packaging Innovations.

Specialising in pre-press FMCG packaging services and flexographic printing plate production, Reproflex set up a mock up division at its Cramlington site in 2002 to offer packaging samples. This now accounts for 15%, but R3 is hoping to grow that side of the business to 25%.

Benedict Moore, marketing manager, explained, ‘We have a HP Indigo and we complete mock ups by hand in small to medium numbers. But creative agencies and brands are increasingly asking for physical mock ups with special finishes applied. We also recently started working with a London agency that has a lot more jobs to give us on the basis that we expand our capabilities and capacity.’

With the Oris Flex Pack // Web system, which includes the Roland VersaCAMM VSI inkjet printer/cutter, running XG Inks onto a range of specifically manufacturer substrates, Reproflex 3 can readily make colour-accurate packaging mock ups in house. As a result of re-defining the eight-colour inkset to include orange, green, white and metallic contract-proof quality mock ups can be achieved.

The LEF-300 direct prints onto a whole range of substrates and objects for customisation of products including branded merchandise, industrial goods and prototypes. It has four print heads and two UV LED lamps and runs white and clear (gloss) ink. In the Oris Flex Pack system, it is used together with a custom-made punch and register system to print matter/gloss spot varnishes and to create embossing effects.

The software also allows production of metallic spot colours directly to substrate and can match original stock used in flexible packaging, ranging from aluminium foil to shrink film.

Mr Moore said, ‘Colour accuracy is very important and why we chose these solutions. While these are mock ups, they still need to be of a very high quality especially as we want to be pushing into the premium end market. The press size and colour gamut also opens massive new doors for us. With the new system we can reproduce complex finishing effects, so customers have a tactile experience when interacting with our prototypes.’

The latest deal follows the integration of Oris software that enabled Reproflex 3 to upgrade its conventional Epson proofing with both contone and halftone dot proofing. The solution was installed at the company’s Cramlington, Dubai and Bristol sites, driving a range of Epson printers.