Discover superior efficiency and ultimate consistency with Apex GTT 2.0

Serving more than 11,000 customers in all worldwide markets, Apex International (Apex) is renowned for delivering the highest quality aniloxes that deliver optimum print results, earning an enviable reputation as the global leader of anilox and embossing technologies. With its Genetic Transfer Technology (GTT) displayed at Labelexpo 2025, Apex offers a revolutionary approach to printing by utilizing a unique ‘slalom’ engraving instead of traditional anilox rolls. Here Joris Cabri, VP of Sales for Europe & Africa with Apex looks at how the GTT aniloxes deliver significant improvement over traditional cell-based engravings.

Colour consistency key to success

“The GTT 2.0 anilox is specifically engineered to mitigate liquid turbulence and deliver a calm liquid surface,” said Joris Cabri. “This is achieved through improved engraving which ensures up to a massive 50% reduction in cell wall surface area across the anilox, while also decreasing the required channel depth by an average of 25%.

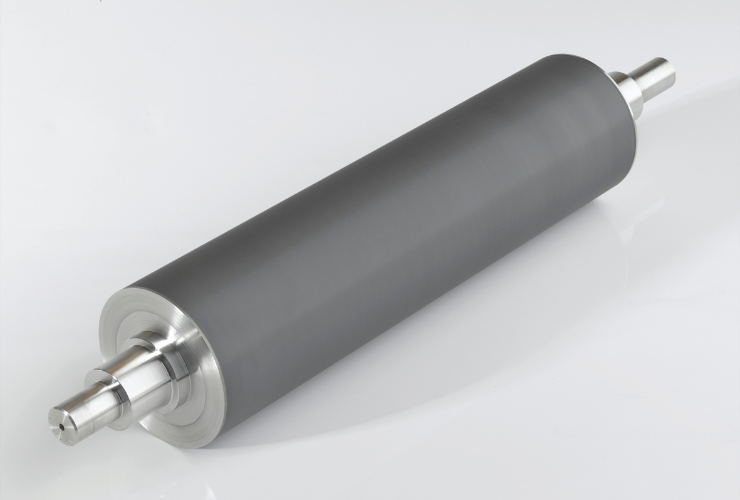

The Apex GTT 2.0 anilox will be featured at Labelexpo 2025

What’s more, as well as fine-tuning the GTT’s existing volume options, Apex has now added further additional volume options. This means the benefits of GTT are now available to those businesses who historically could not get the correct colour on press, giving printers the flexibility they need to use GTT 2.0 and secure consistent colour across all their print jobs.”

From booth 5G40 in Hall 5 of the Fira Gran Via convention centre, Barcelona, Joris and the Apex team will showcase how the unique design of GTT engravings offers substantial operational benefits, including reduced maintenance and enhanced press uptime. “Printers have observed a notable decrease in the need for plate cleaning and maintenance, which results in more consistent print quality and longer uninterrupted runs,” said Joris.

“For example, one facility experienced fewer stoppages for plate cleaning and significantly less ink build-up over a 160,000m print run.

“Importantly, our GTT anilox engravings not only enhance print quality, but they also significantly reduce ink consumption, promoting cost-effective printing practices that are also more in line with sustainability objectives.”

Extended Colour Gamut made simple

With proven operational benefits and enhancements in ink efficiency, GTT technology stands out as a strategic investment for businesses focused on quality, cost reduction, and sustainability. In addition, GTT offers precise control over ink transfer and volume, leading to superior print quality with vibrant colours and sharp details.

“At Labelexpo 2025, we’ll demonstrate how the technology optimises ink release, reducing dot gain and enhancing print consistency across various substrates,” said Joris. “Furthermore, GTT enables printers to achieve higher colour densities and smoother gradients, crucial factors for complex ECG applications.

“Printers have observed a notable decrease in the need for plate cleaning and maintenance, which results in more consistent print quality and longer uninterrupted runs”

“By improving print performance and reducing downtime for cleaning and maintenance, GTT supports cost-efficiency and sustainability in flexographic printing operations,” he said. “We look forward to using Labelexpo 2025 to showcase how GTT anilox engravings play a pivotal role in advancing ECG printing capabilities to achieve superior results. Our GTT 2.0 technology is not just a viable option but is the preferred choice for achieving exceptional print results in flexographic applications.”

Discover Apex GTT 2.0 at Labelexpo 2025. Visit the Apex team at booth 5G40 at Labelexpo, in Hall 5 of the Fira Gran Via convention centre, Barcelona, from 16-19 September 2025.

This article is an advertorial; the featured company created the wording and paid for its placement. It has been checked by Whitmar Publications to ensure that it meets our editorial standards.