Nilpeter has announced a new customer engagement programme in the United States for 2026, featuring a series of in-person events aimed at providing converters with hands-on access to its technology and expertise.

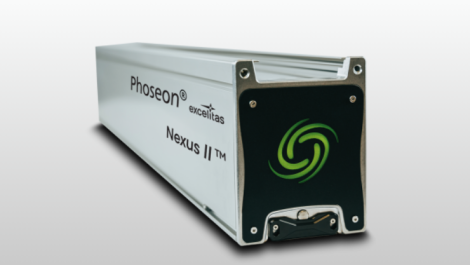

The first event will take place on 22 April in Cincinnati, Ohio, and will focus on flexible packaging and food safety. It will include demonstrations of Nilpeter’s FA-Line series, along with presentations from GEW, Actega, Multi Plastics and Karlville. Kevin Kollman, president of Prime Packaging, will deliver the keynote address.

Additional events are planned throughout 2026 at Nilpeter’s Technology Centre in Cincinnati, which houses multiple presses for live demonstrations and application development. The programme is intended to offer practical insight into production workflows, flexible packaging solutions and expanded gamut printing under real operating conditions.

Lenny DeGirolmo, president, Nilpeter USA, said: “The US market is strategically important for Nilpeter, and the best way to support our customers is to open our doors and show what we can do – not in theory, but in real production conditions. When customers can see the presses running, bring their own jobs and questions, and spend time with our specialists, the conversation becomes much more meaningful. These events are about creating closer partnerships, sharing knowledge, and helping converters make confident decisions that improve performance and competitiveness. Cincinnati gives us a unique platform for that, and we are excited to welcome both existing customers and new prospects throughout 2026.”

Martin Teilberg, global marketing manager at Nilpeter, added: “We have been exploring the idea of activating our Technology Centres much more strongly for a long time, and 2026 is where that ambition becomes very tangible in the US. With a number of events, we can invite customers into an environment that is built for learning, dialogue and live production insight. In Cincinnati, we are able to demonstrate flexible packaging solutions and expanded gamut capabilities in real conditions, with time to go deep into applications and optimisation.”