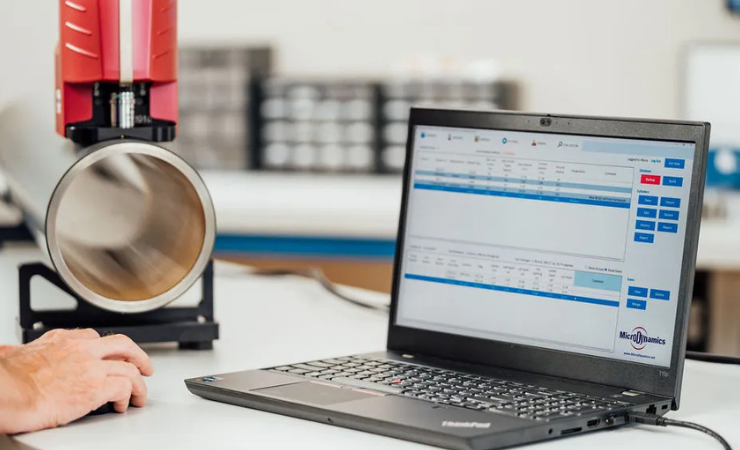

Manufacturer of surface profile inspection systems MicroDynamics has released an update for its inspection system, MicroScan. The new Version 3.7 provides new features, automations, and improvements to ensure a smoother and more connected user experience for MicroDynamics customers.

With MicroScan 3.7, MicroDynamics has expanded roll data fields to include standardised cleaning parameters and run length information for each roll. The update also allows multiple database organisations so users have the freedom to organise anilox roll and gravure cylinder data by press, facility, status, application or whichever parameter they choose.

The latest version also offers new automated features, making it faster and smarter than ever, explained the company. MicroDynamics systems can now check your current scan settings and automatically recommend the appropriate magnification combination for your roll or sleeve volume. Additionally, the Veritas inspection instrument can now be integrated into automated equipment, such as printing presses, wash up systems, laser cleaners, and more. With integrated software, operators can automatically take and view MicroScan measurements, using the integrated system’s HMI controls.

As far as performance updates, this new release offers improved gravure cylinder scanning, better cylinder search functionality, and enhanced history plot displays, visualising plots by run length or by time. Other improvements include corrected surface height value display during wide field mode, a correction to the most recent values shown for certain measurements, and miscellaneous minor fixes and adjustments to improve the user experience.

Lastly, MicroDynamics solutions are now capable of installing future updates across all users automatically, without the need for company intervention. The company added that these automatic updates will contribute to real-time, industry-wide standardisation of surface profile measurement—from roll suppliers to printers—the entire supply chain will be in-sync with fast, accurate anilox inspection solutions.