Matching brand colours is a fundamental task for most flexo printers, and there are tools and approaches that can take the subjectivity out of colour management.

How do you manage colour at your flexo facility? For some flexo companies, it seems, the question itself might engender something of a feeling of discomfort. There is a diplomatic response provided by X-Rite’s director of print & packaging, Jon-Michael McCartney, when asked about the industry picture.

“The level of advancement in colour management varies quite a bit among flexo printers,” he tells FlexoTech. “Some are already using advanced digital tools and following ISO standards, while others still rely on more traditional and subjective methods. However, as demand for colour consistency continues to grow, especially in packaging and branding, more flexo printers are recognising the need for digital process control and colour measurement tools to remain competitive.”

There is a slightly more straightforward response from Niall Coady, the owner of colour consultancy MPXColour, who points out that there is no standard way to communicate colours in the flexographic printing industry, even though there is a standard for controlling the printing process (ISO 12647-6:2020). This lack of a standard makes it hard for brands and printers to control the results and make sure their products are of the best quality.

Mr Coady explains: “Many printers buy their plates and separations from independent repro organisations who have limited printing experience and rely heavily on proofs printed on different materials than the final product for the client. I’m often puzzled by the number of businesses using 1990s methods in 2025 software and expecting better results. To get the results we want, we need to change how we do things; that’s a fact.”

MPXColour helps its clients, including printers, agencies, and brands, develop a colour communication strategy. It uses science to make a process that is often too subjective, more objective. Mr Coady says: “What can be measured can be managed.”

“That’s the ethos behind the way I have been doing my business for the last 10 years,” he continued. “One of the key things I get involved with is when a brand wants to understand what they are asking a printer to do.”

Colour strategy

For printers, managing colour expectations for different brands is a complex process that can easily result in them having to work with lots of different colour management software and tools.

“It’s a huge job for them to keep up with this. I ask brands: what are you trying to control, what’s the goal and how would you describe that to your printer? If you ask that very specific question to five different brands you will get five different answers. There has to be a common denominator and that’s what I do. I act as a communications man between what a client wants to achieve, what a printer can actually achieve and what the process can achieve, given the materials and components designated for the job.”

Data-driven

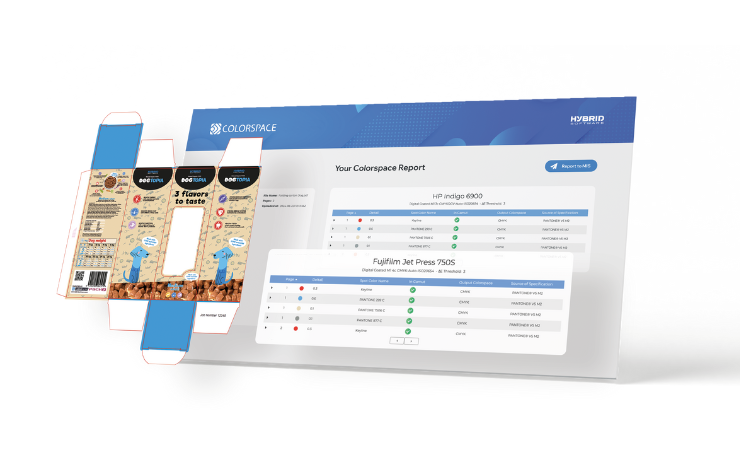

Hybrid Software also sees the process as beginning with brand owners, creating artwork and specifying colour in an unambiguous way.

Joris Verbouwe, product manager for colour technology at Hybrid, comments that “if colour is well specified then we have a very good starting point”. He adds: “It’s an essential thing to make colour an integrated part of a production process, in our case with Cloudflow. It’s very much data-driven, it’s colour-by-numbers. But it’s also about staffing; the people you have interacting with Cloudflow. You cannot expect everyone to be very colour-savvy, and for printers to have skilled people focusing on colour is great but this can lead to production bottlenecks, but with Cloudflow workflow everyone in the production process can make colour production decisions and evaluate the outcome without being a colour expert.

“So, it is data-driven, logical, intuitive. In the workflow, you can prepare the artwork for output, but you can reroute to whichever press you want it to go to. You can use the flexibility in the workflow to do that and you can do it very late in the process – what is called ‘late binding’.”

Removing subjectivity

There is a key point here about rerouting print jobs to a different press. The “colour-by-numbers” approach theoretically enables this to happen, by taking any subjectivity out of colour matching.

X-Rite’s eXact 2 spectrophotometer

Jon-Michael McCartney of X-Rite explains: “The most effective way to remove subjectivity from the colour management process is by using digital colour standards based on spectral data. This approach helps designers share colour intent and specifications while setting clear requirements across the entire print supply chain. With digital colour communication, everyone is speaking the same language and working off the same specifications, which eliminates subjective interpretation.

“By implementing a digital colour workflow, brands and their print suppliers benefit from faster make ready times, improved productivity, and reduced waste. By measuring and verifying spectral colour data, flexo printers can maintain colour accuracy throughout production and share results with brands as part of a print quality control program. This process not only minimises costly rework but also reduces the need for onsite press approvals, accelerating production timelines and supporting sustainability initiatives through reduced waste and resource consumption.”

It is certainly not an easy process to implement. Each flexo press must be fingerprinted, while profile information on different substrates must be compiled. Colours on samples can be measured with a spectrophotometer and stored as a CXF file, which allows the data contained within to travel the world over, and be applied to a specific printing press, specific printing conditions, and specific substrate, to provide a realistic expectation of the colour that can be produced.

“By digitising colour standards, printers can store and access spectral data for precise colour reproduction across different presses and substrates. These tools allow printers to work within predefined tolerances, eliminating guesswork and ensuring colour accuracy from proof to production – no matter the material or printing conditions,” said Mr McCartney.

He concludes: “If there’s one key takeaway, it’s this: strong process control is the foundation of colour consistency. Invest in the right tools, maintain your equipment, and carefully manage environmental conditions in the pressroom. Adopting a digital colour workflow provides a path to streamlined colour communication, waste reduction, and increased efficiency.

Implementing a colour communication strategy at Reflex Group

Reflex Group first brought in MPXColour in 2016/2017, tasking it with implementing an automated colour calibration and conversion solution to four-colour fixed palette for both flexo and digital printing. The intention was to deliver best matches to the Fogra39L colour space and best predict Pantone colour separations to print under a deltaE of 2.5 on various presses.

The solution created by MPXColour involved ColorLogic tools and a custom calibration system for flexo print. The system is integrated with X-Rite ColorCert for print quality control, using X-Rite’s eXact instruments, linked to Netprofiler for accurate colour measurement; it utilises ColorLogic’s Zepra for accurate spot colour conversions. Using this system, Reflex can quickly and easily repurpose any file or brand spot colour blend for accurate reproduction on any press in the group.

Ben Cox, director at Reflex Group and its Graphic Brands creative agency, told FlexoTech that the system gives the business consistency and flexibility. “We’re in the GMG world for proofing, the Esko world for profiles and the X-Rite world for moving colour around – everything in one area, which is really unique,” he said.

“With this workflow we can take a set of plates from one site and send them anywhere else in the group with a single colour management strategy to replicate the print result. It gives us contingency as well, in case a production site should go down.”

At Graphic Brands, a “Proof Plus” service sees the business produce proofs, or “prototypes”, on the actual substrate for the print job, utilising the print conditions of the press that will be used. These are run through a wide format inkjet printer, using colour management profiles developed for a wide range of actual label stocks.

The results speak for themselves. Mr Cox comments: “I have come from a background where we were getting more than 30 colour matching issues per month, and at Reflex we just don’t see any of that at all.