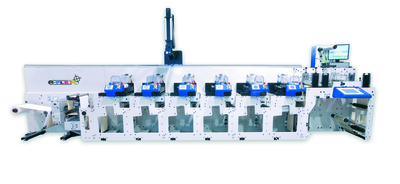

Edale has launched the FL-3, an automated press available in both 350 mm and 430 mm versions

New narrow web flexo presses show trends towards more automation, shorter web paths and wider widths, reports Nessan Cleary.

The recent Labelexpo show saw a number of new narrow web flexo presses launched as well as enhancements to existing models.

Taken as a whole these highlight the ongoing trends in this sector, with more automation for less wastage and lower running costs. There is a clear move toward cheaper presses as well as to wider web widths as vendors try to target more packaging applications.

Return to conventional

But the biggest issue is the extent to which digital presses have put pressure on the flexo press manufacturers.

Almost every flexo press manufacturer we spoke to mentioned digital label presses and the need to be able to compete on shorter runs. It is clearly the technology to beat even though flexo is still unquestionably the dominant system in narrow web work.

James Boughton, managing director of Edale, estimates that as many as 20% of label presses sold recently are digital, while only 1% to 2% of jobs are actually printed digitally.

‘But,’ he added, ‘we are seeing that a lot of the early adopters are coming back and investing in conventional manufacturing.’

However, Mr Boughton said that digital technology has also had a positive impact on conventional presses, which he said are now three times as productive as they were 10 years ago.

‘They are much quicker to set up and the machines run at higher, more consistent speeds so that you can do some short runs down to a few hundred metres.’ This includes features such as automatic loading of dies and slitting. He continued, ‘The big thing with narrow web flexo presses is making them more efficient and quicker to set up and able to compete with the digital press technology that is becoming quite well established nowadays.’

This can be seen on Edale’s FL-3 press, launched at Labelexpo last year, having been previously seen as a prototype in 2011. It has a short web path, with less than 20 metres of setup waste, and can be set up in under 10 minutes. Available in both 350 mm and 430 mm versions with speeds of up to 200 m/min, it uses automatic registration and has dual axis servo drives to reduce makeready time. It runs substrates up to 450 micron in thickness, depending on the configuration. Options include foiling, lamination, slitting and rotary screen printing.

Mr Boughton also said that there is a noticeable trend for wider presses. Edale is currently building the first of the FL- 5 presses, which should be fully launched by the middle of the year.

The FL-5 essentially adds some of the advantages of the FL-3, such as the shorter web path, to the older Gemini platform. It will handle a wider range of substrates – up to 600 microns – and has a higher degree of automation.

According to Mr Boughton, cold foil has become fairly standard and customers sometimes add gravure heads for special items such as printing metallics on cartons. Single colour digital heads are also sometimes requested to put barcodes and code numbers onto prints. Commenting that the print quality of flexo presses has improved in recent years, he also added, ‘There is a lot more automation that can be driven by job data files.’

The e-Flex from Focus Label is a fully servo-driven, modular press with a choice of drying systems

The e-Flex from Focus Label is a fully servo-driven, modular press with a choice of drying systems

Servo-driven efficiency

Focus Label Machinery launched a new mid-range flexo press at last year’s Labelexpo. Available in 330 mm or 430 mm widths, the e-Flex is a modular press with twin digital drive servo technology for rapid adjustment.

Sales manager, Antony Cotton, said that its main advantage is that it is fully servo driven. ‘You can control all of the rotating parts of the machine a lot more efficiently. There is a premium over using a line shaft with a gear box, but there is also reduced wastage, set up and downtime so you make that back.’

An inline digital inkjet module, manufactured by Industrial Inkjet, can be added to print variable data in mono or full colour. The print stations have an open architecture for easy loading of ink cartridges as well as individual HMI control panels allowing the press to be controlled from any print station. It features heavy duty die-cutting units that can cut through substrates from film to cartonboard up to 380 microns.

There is a rail system that allows optional add-ons to be positioned anywhere across the web.

The press has a choice of drying systems, including full UV, LED, infra-red – or combination drying systems, with optional chill rollers for heat sensitive substrates.

Saving on power

One of the main competitors is the Performance Series from Mark Andy, of which the most popular are the P3 and P5. Both come with a choice of widths 250/330/430 mm and run at 230 m/min. They offer a choice of ho air, UV or LED drying and use inline rotary die-cutting. The main difference between them is that the P5 boasts servo-driven functions, which allow it to handle more complex substrates. UK sales manager, Paul Macdonald, said that this is important because packaging is a growing market for these presses.

The P3 on the other hand is a good budget option. Mr Macdonald explained that the main challenge facing customers is the demand for quicker makereadies, pointing out that repeat cylinders can be changed in seconds, and colours in under three minutes. He said that there is a move towards greater automation but that customers are mainly looking for lower power consumption and reduced waste, noting, ‘These are the two biggest outlays that can affect profitability for a company.’ Thus Mark Andy demonstrated a ProLED UV curing system on a P3 press, which should lead to much lower energy costs. It also features the Quick Change Die Cut system on the P5 and P7 presses, which allows operator to change die cylinders in around 30 seconds. A hybrid digital press is being developed in house with availability in Europe by the end of the year.

Mark Andy also owns Rotoflex, which produces inspection, slitting and rewinding equipment. Mr Macdonald said that most presses are sold with a Rotoflex unit. Rotoflex recently updated its VLI rewinder for film and flexible packaging with a new URC 2.0 control system. This is available in widths up to 700 mm and supports higher speeds and tension-specific applications.

Addition to the line up Dutch press manufacturer MPS recently launched its new entry-level EB press. This is a mechanical press that will run pressure-sensitive label stocks, including some PP and PE materials but not cartonboard. It has a 370 mm web width, a short web path and a maximum speed of 165 m/min. There is a choice of drying from UV, IR and hot air. Nick Tyrer, sales director at MPS UK, explained that it was designed to plug a gap in the line up. ‘We tended only to be considered when people were well established and we wanted to have an opportunity to sell machinery to smaller companies.’

It will work with all of MPS’s standard options, including foiling, relaminating and de-laminating, which can be positioned anywhere along the press due to a rail system. There is also an upgrade to a more advanced program controller. The first of these has been ordered by Hine Labels in Rotherham, Yorkshire.

MPS also tweaked its EF press range, including a standard model with a basic automation package featuring Job Memory, iControl and Gearless Tooling. There is a version with automatic print control plus an Advanced option which can memorise settings such as registration, corona and UV drying.

Mr Tyrer said that we will see more automation as the flexo press manufacturers seek to counter the threat from digital devices. He pointed out that many customers already have one digital press and are having to decide between buying another or a flexo press. He said, ‘The level of automation on a flexo press means that the job set up and wastage is no worse than it would be for a digital press.

The more the press can be digitised and the more facets of a job that can be stored, the faster it will be because the operator doesn’t have to memorise what the corona or registration settings are.’

MPS has also worked to bring Kodak’s Spotless flexo technology to narrow formats. This can give a very wide colour gamut so that it is possible to hit special colours using just four or five colours, making jobs much more economic.

Flexibility

Gallus has a wide range of narrow web flexo presses. It recently announced a ‘Plus’ update to the ECS 340. This includes a number of additional features such as a screen printing unit, more powerful UV curing and a software update that can increase the maximum print speed.

This can be retrofitted to existing presses. The ECS 340 is a solid machine with a granite core and an extremely short web path of just 1.1 metre between printing units. It has a 340 mm web width and runs at 165 m/min and print on a range of substrates from pressure sensitives to cardboard.

Gallus’s most popular press in the UK is the RCS thanks to its flexibility in being able to quickly change over between printing technologies, from flexo to screen printing, offset and so on. It is a highly automated servodriven press that can handle pressuresensitives, plastics, paper and cardboard. It is available in 330 mm and 430 mm widths, and runs at up to 160 m/min.

Wim Brunsting, managing director of Gallus UK, said that we will see more automation in the future, noting, ‘The conventional machines will have to be able to cope with much faster changeovers and reduced waste.

Run lengths are getting much shorter – down as low as 900 metres for some jobs – and customers have to cope with more jobs per shift.’ But Mr Brunsting doubts that digital presses will dent the demand for narrow web flexo, noting that the market for labels is very diverse. ‘We are selling a lot of conventional presses now with everything, such as embossing, hot foiling and screen printing because people want their bottles and their products to look nice.’ He added that digital labels can sometimes look a little flat and that you need a conventional press to add effects, such as embossing.

This P3 from Mark Andy is an entry-level press, while the servo-dr iven P5 has similar features but more automation

This P3 from Mark Andy is an entry-level press, while the servo-dr iven P5 has similar features but more automation

Digitising flexo

The Italian company Gidue has concentrated its efforts around its ‘Digital Flexo’ concept, which aims to automate the loading of plate cylinders and flexible dies so that the presses can keep running between jobs. Thus on the new M5 press, operators can load the next plate behind the one in use for a fast changeover between jobs without having to stop the press.

Gidue has also made good use of inspection cameras so that the system can recognise when one job has changed to the next and automatically change the settings appropriately.

The aim is to reduce the level of waste to near zero to compete against digital presses.

There is also has a new entry-level press, the MX2, for producing pressure-sensitive labels. This has a fixed configuration of eight flexo units, with UV lamps plus one die-cutting station and cold foil, with a 370 mm web width. It is a belt-driven machine, with a short web path, which Gidue claims will be virtually maintenance free. One of the first customers is Flexiprint, a Sri Lankan company producing tea bag tags and envelopes. Flexiprint also ordered an M1 digital flexo press, configured with a 370 mm web width and 12 UV waterbased flexo units, as well as three diecutting stations and punching units for the tea bag tags and envelopes.

Going wider

Nick Hughes, managing director of Nilpeter UK, also said that there is a trend towards wider presses for packaging, but he makes the point that customers tend to stick to one application, be that labels or packaging, so that label customers are not using the wider widths to diversify into packaging.

Nilpeter introduced the latest model to its FA line at last year’s Labelexpo. The FA-4* has a 420 mm web width, with an extra short web path. It boasts a new print to cylinder registration system and uses the new ‘Quickchange’ magnetic die modules plus there is an easy load sleeve system for fast makeready. It can run at up to 175 m/min.

The company also launched the new FB-3, which runs at 228 m/min and features a number of servo motors, giving it a high degree of automation for loading and changing jobs, and the ability to store job, impression and registration settings. It can be used with UV and water-based inks and has a width of 350 mm.

In addition, Nilpeter announced the MO-5, which is a wider version of the existing MO-4 with a 520 mm web width running at up to 200 m/min.

It is really aimed more at the packaging rather than the label market. It is a servo-driven machine that uses automated water-balance and ink key controls, and automatic registration. The first one has just been installed at the Brazilian converter Baumgarten, complete with six offset units and two flexo as well as die-cutting and lamination.

Final word

In conclusion, most of the new machines that we have covered here have been about press manufacturers rounding out their offerings to cover all bases. Much of this is about countering the perceived threat from digital devices, hence we have seen cheaper, entry-level flexo presses as well as much more automation and shorter web paths to cope with shorter run lengths. Inevitably in the future some of the automation that is common to the top of the range presses will start to appear on the entry-level models, just as there is likely to be emphasis on improving workflow, for such things as ink settings, and for storing settings for registration, corona and tension for individual jobs.

Gallus’s most popular flexo p ress is the highly automated and flexible RCS

Gallus’s most popular flexo p ress is the highly automated and flexible RCS