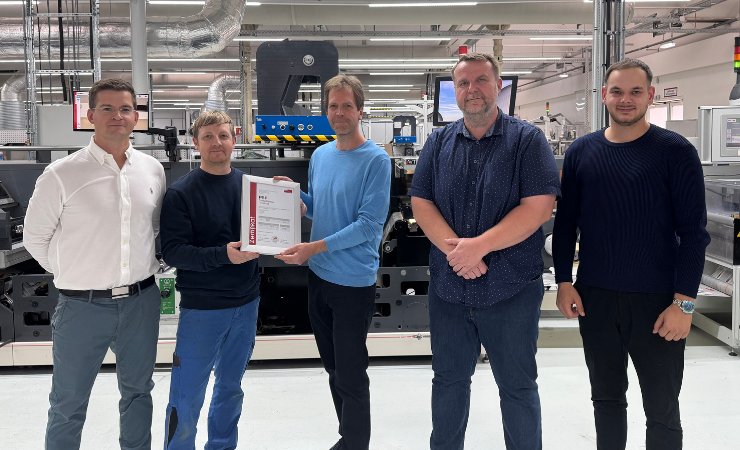

German flexo printer Thüringer Papierwarenfabrik has become the first in the world to achieve the newly developed ProcessStandard Flexo (PSF) certification from printing and media technology research institute Fogra.

Introduced this year, the standard and its certification are designed to streamline production processes and improve colour communication between printers and clients.

According to the managing director of Thüringer Papierwarenfabrik, Torsten Dreke, the company pursued certification to optimise workflows, strengthen quality standards, and enhance customer satisfaction. Head of prepress at the company Stefan Rößler noted that the PSF framework supports cost efficiency, sustainability, and consistent quality results.

The PSF defines requirements for both production printing and proofing. Using a fingerprint and evaluation scheme, it assesses colour space and tone value reproduction. Developed by Fogra in collaboration with industry partners, the standard provides measurable criteria for flexographic print quality and supports clearer communication across the supply chain.

“PSF enables measurable flexographic print quality and simplifies communication between clients, repro houses, and printers,” said Jürgen Gemeinhardt, head of printing technology at Fogra.

Optional certification allows printing companies to demonstrate production quality, while clients can use PSF certification as an assurance of consistent standards.

According to Fogra, interest in the new standard is growing, with additional certifications already underway. Fogra has also introduced a new certification programme for water-based flexo cleaners, allowing approved products to be used in Baldwin washing systems without affecting warranty conditions.