Baumer has unveiled an expanded and updated range of systems for adhesive application and quality control on flexo folder gluers (FFG), with its CorrBox Solution product family.

The three models – go, evo, and pro – are tailored to meet the diverse needs of the corrugated packaging market, explained the company.

The new CorrBox Solution go replaces the previous FFG go system and is designed for simple adhesive application. The CorrBox Solution evo and pro take things further by integrating quality control and supporting multiple configurations for maximum flexibility.

“Our new and modular CorrBox Solution product family gives customers all the options they need to tailor gluing and quality assurance to their FFG applications more closely than ever before – economically and technically,” stated Thomas Walther, head of corporate strategy and innovation at Baumer.

Built on Baumer components – such as the PX 1000 multi-application head, KPE 6 and KPE 9 adhesive pumps, and an intuitive HMI – all three CorrBox Solution systems offer reliable control and high application precision from the first product on.

The CorrBox Solution evo targets high-volume corrugated packaging manufacturers who require speed, quality, and efficiency. Available in one- or two-sided configurations and with the optional Inverto unit for top/bottom application, the evo offers short setup times and fully integrated quality control, making it ideal for large-scale production of folding boxes and shipping containers, explained Baumer.

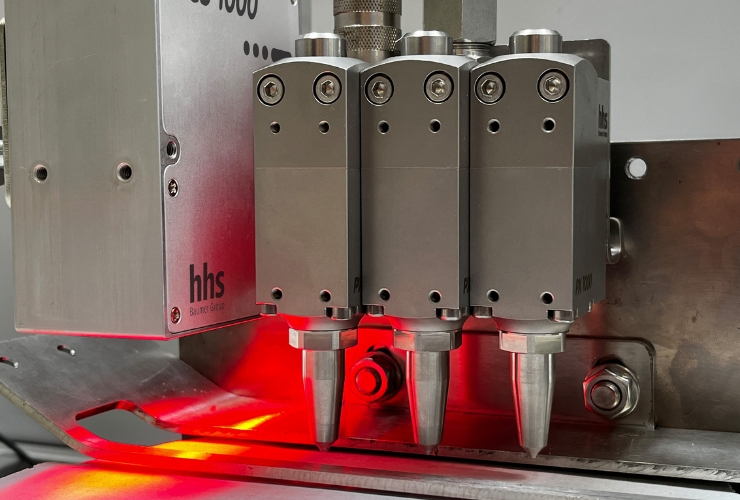

On white corrugated, the CS 1000 detects blue-coloured adhesive with the help of red light

At the centre of the system is the PX 1000 head. Combined with Baumer’s pump technology, it can offer, says Baumer, high-precision glue application.

The CS 1000 sensor, developed specifically for the evo system, monitors every glue strip. The company said it delivers excellent results when there is contrast between adhesive and substrate – perfect for brown board and blue glue or white board and clear glue. These combinations represent roughly 80% of standard RSC folding box production.

For more complex substrates, the CorrBox Solution pro can be paired with the PGD 1000 sensor, which monitors adhesive application.

“Our CS 1000 sensor is a cost-efficient solution that reliably monitors every strip of glue,” explained Mr Walther. “The PGD 1000, on the other hand, has virtually no limitations – it’s ideal for converters who need maximum flexibility and precision.”

Baumer offers two pump options to tailor each system to specific adhesive needs. The KPE 6 is a compact choice for adhesives up to 5000 millipascal-second viscosities, while the KPE 9 handles adhesives up to 10,000 millipascal-second viscosities.

CorrBox Solution go uses the Xact controller, suitable for basic gluing tasks. CorrBox Solution evo and pro are equipped with the Xtend3 controller, known for its user-friendly interface and advanced functionality. The Xtend3 in the pro version offers expanded application and monitoring capabilities.

All three CorrBox systems include Glue Save Mode, a stitching feature that reduces adhesive use by up to 50%.

“I often wonder why so many folding box producers hesitate to take advantage of this opportunity,” said Mr Walther. “Adhesive is often seen as just another consumable, but the savings potential is real.”

After field testing over recent months, the CorrBox Solution evo is now available to order from 1 October 2025.