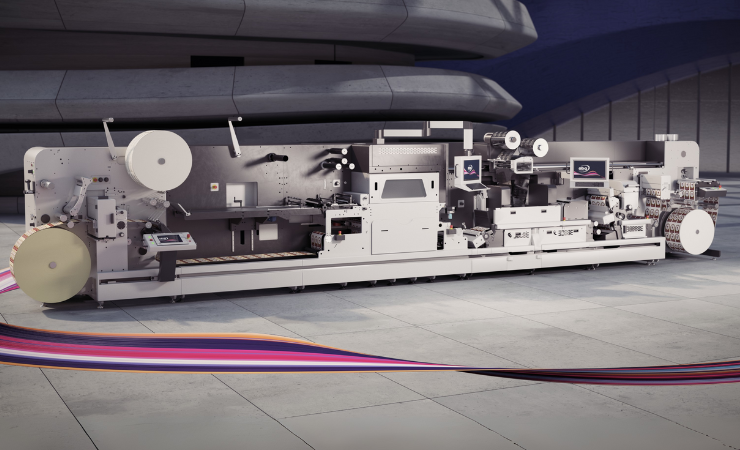

AB Graphic International (ABG) has introduced the DigiLase Duo, a digital laser cutting system featuring two independent laser sources. The new configuration is designed to improve speed, precision, and operational resilience in digital finishing applications.

Developed in collaboration with one of ABG’s customers, the DigiLase Duo aims to address production challenges in high-volume and web-to-print environments. By using two separate laser light sources instead of one, the system can operate at up to twice the speed of a single-laser setup. This also introduces redundancy, allowing production to continue if one laser experiences a fault.

A key feature of the new system, according to ABG, is Repeat Flow, which enables automated switching of die lines within each web repeat. This eliminates manual adjustments and material waste, making it suitable for short-run and custom jobs.

The DigiLase Duo also integrates with ABG Connect, the company’s digital workflow platform. According to ABG, this integration helps reduce waste during job changes and supports more resource-efficient production.

Mark Norman, technical director at ABG, said the system was developed in response to customer feedback and internal software development efforts. “By introducing dual independent lasers, we’ve been able to deliver gains in speed, flexibility, and reliability, while also helping customers to minimise waste,” he said.