Provider of prepress services and flexographic printing plates, Spirit Packaging Premedia, has introduced a new digital tool aimed at improving efficiency and transparency in the flexographic printing process. Based near Aachen, Germany, the company has served the packaging industry for over a decade.

Spirit recently enhanced its production process for flexo plates used in corrugated packaging. The updated method uses a one-step laser imaging process to expose precisely cut plate segments on a carrier film. This approach reduces material use and improves press performance, maintaining high print quality and registration accuracy, even in small polymer areas.

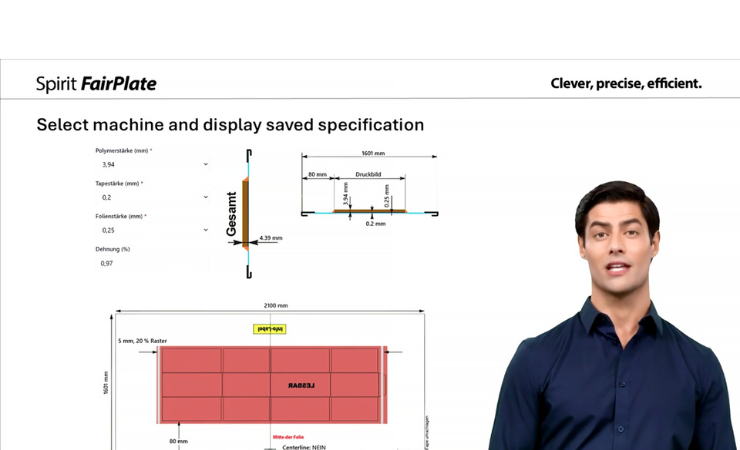

The latest innovation supports the launch of the FairPlate Cost Calculator, part of Spirit’s forthcoming online shop. The tool will allow users to estimate costs, place orders, and access technical data in a single platform. The shop is designed to be accessible around the clock and caters to both technical and commercial users, including customer service and procurement teams.

“Reprographics and flexo plate production are still largely manual processes – labour- and cost-intensive,” said Mattijs Mennens, partner and chief operating officer of Spirit Packaging Premedia. “Our vision is to digitalise, standardise, and streamline both technical and administrative workflows – always with the goal of delivering real added value to our clients. In close cooperation with customers, we’ve developed new concepts that we’re now implementing step by step.”

The new online service aims to make the ordering process more efficient: users log in, upload artwork, select a press, calculate costs, and submit an order. The platform is set to launch soon.