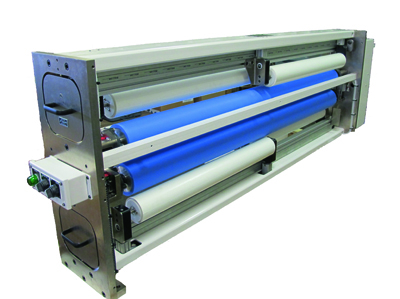

Polymag Tek’s NNWCDS Contact Web Cleaner provides two-sided cleaning with two sets of overlapping tape rolls to remove contaminants from the two Polymag Tek Blue-STM Contact Cleaning Rolls’ (CCRs) surfaces

A clean web is essential for efficient production. The presence of contamination is an inevitable by-product of high-speed machinery, but through effective web cleaning productivity can be increased and maintenance, downtime, and waste minimised. Michal Lodej reports.

Web contamination can occur in the form of dust, dirt and other assorted particles held within the boundary layer, which is created by any moving web. When the web is moving it drags along air with it and as it moves this ambient air forms a boundary layer which will trap any contaminants on the web. A slow moving web will have a thinner, low density boundary layer; on faster webs this layer will have a higher density and will be thicker.

There will also be contamination stuck to the web surface by the generation of static charges. An effective web cleaning solution must be capable of tackling both. Contamination types and levels differ, as do the reasons why web cleaning is necessary so choosing the correct technology is important.

The main web cleaning techniques are contact web cleaning and non-contact web cleaning. During contact web cleaning, the substrate comes in physical contact with a polymer contact cleaning roll or brush. The contact with the web ensures that the boundary layer of air is broken so that particles are not held to the surface of the web by laminar flow. Contact cleaning often uses adhesive tape or fabric as the collection method. Various configurations are available based on contamination level, substrate type, speed, tension and product end use.

Non-contact cleaning usually involves a high flow vacuum hood that sucks particles from the web’s surface and collects in a dust collector. Non-contact cleaners often incorporate static elimination bars and air knives to assist in removing particles.

When to use what

In general terms, non-contact cleaning works best when contamination is heavy, particle size is large (>50 microns) and speed is slow. They also work well when running substrates that are sensitive to contact. Contact cleaning tends to work better on substrates that have low to moderate contamination, removing particles down to 1 micron at all speeds.

Contact cleaning systems, such as Meech’s TakClean, incorporate twin elastomer and adhesive rollers to physically pick up and remove dry, unbonded contamination from a moving web. These systems are in contact with the full width of the web, mechanically breaking the boundary layer of air and to lift contamination from the web’s surface. The second roller, with surface of which has a high adhesive mass, picks up the debris from the first roller, preventing recontamination.

The SC CCK (Superclean Contamination Control Kit) from KSM Superclean is a contamination collection station. In this kit customers receive one SC RPH (Superclean Roller & Pad Holder) a portable holding station for an adhesive pad and hand roller; one SC CR (Superclean Cleaning Roller), and one SC AP (Superclean Adhesive Pad) supplied with one adhesive pad.

The SC CCK (Superclean Contamination Control Kit) from KSM Superclean

No touching

For a non-contact cleaning application, such as Meech’s CyClean, an efficient blow-and-vacuum system is used. Powerfully blowing air at either side of the web removes the boundary layer of all traces of contamination. The vacuum airflow captures the airborne debris which flows into a filter system.

Non-contact systems are generally more compact and can be easily integrated into existing presses and converting lines.

The range of applications and materials that flexo printers are expected to handle is expanding. They must be able to meet these new demands with confidence and reliability and do so profitably – installing web cleaning and static control solutions can enable businesses to do this while increasing productivity and delivering consistent product quality.

Once assessments have made with regards to the materials being processed, the application, the flexibility required by the printing line, and the budget, only then can an informed decision be made on which web cleaning and static control products are right for you.

Shocking results

Web cleaning is often paired with static elimination products. This combination goes together well, but static elimination alone is not a web cleaning method. The secret lies in the ability to collect the contamination for removal. Static elimination bars, air knives and blowers will help break the attraction and separate the contamination, but without a collection method, the particles can find their way back to the web.

Neutralising charges on the web’s surface is an essential action, as any static presence will attract dust and dirt. Ionisation systems, including that of Meech’s Hyperion range, can employ high voltage AC or ‘pulsed’ DC output to produce ionised air that neutralises surface charges, preventing recontamination and potential issues when the web is utilised for printing or packaging purposes.

One of the main barriers to printing-press specific overall equipment effectiveness (OEE) in the flexo printing industry is loose contamination present on the material being printed. Regardless of the source of contamination – already present on the new roll of material being loaded on to the press, or being introduced on to the web from the environment or machine and operator activity – the direct result can be a costly cease to production to clean down the press.

Beyond the web

Web cleaning by its name suggests a process dedicated to removing contamination from the web. However there are numerous other benefits to a flexo printer which can be derived from the installation on an effective web cleaner.

David Westwood, sales and marketing manager of KSM Superclean, explained, ‘A key component of any press is the anilox roller whose performance is determined by the cleanliness of the cells. Removing contamination from the web removes one variable from the list of contaminants that can sit in the cells of the anilox roller.

‘Dust in the air, substrate fragments, and other debris can all be carried into the electrode assemblies of the corona treater, and if they accumulate, they can eventually clog the exhaust path of the treater and reduce the air flow rate; all leading to inefficiency of operation and a need to clean the treater. Web cleaning can significantly contribute to the long term efficiency of the corona treater.

‘A key benefit of contact cleaning technology is the collection of the contamination on the adhesive layer. This presents a printing company the opportunity for analysis of the contamination problem leading potentially to long-term corrective action measures which can in turn lead to both operational and financial positive returns.’

By analysing the contamination for type, size and frequency, a company can potentially identify the source of the contamination and implement procedures both internally and with suppliers to eliminate or significantly reduce the problem at source. An example of this might be the identification of a certain type of clothing worn by operators, the solution being to eliminate such clothing from the immediate environment around the press.

Equally fragments of particles from pallets or other media for transporting the reels of material found on the layer might lead to a change in materials used to transport the material.