The first flexo press in the company since 1986 has increased capacity for the Dundee company

As an established and proud proponent of gravure, Discovery Flexibles in Dundee, has a strong affinity for the process which has always been the benchmark for high quality printing. However, perhaps there is a change in the waters, as even this gravure stronghold could not resist the power of flexo. Michal Lodej went to see for himself.

The history of Discovery Flexibles stretches back to 1866 when under a different name it produced jute, a rough fibre made into sacks for transporting goods. It was not until 1956 that the company began producing plastic flexible materials and soon began to decorate them as well.

Since then, the evolution of printing has come a long way with Discovery leading at the front, accomplishing many industry firsts. The company pushed on with its own PE extrusion, PVdC coating, inline cold seal application, and solvent free laminating. The company was also one of the first to run a triple lamination facility, all in one pass.

The factory runs 24 hours a day, five days a week and has three gravure presses, seven, eight and nine colours respectively, with the largest going up to 1120mm.

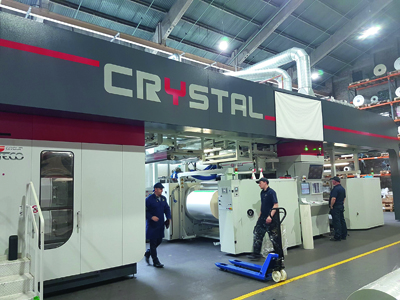

However it is the company’s most recent installation which is causing so much interest; its one and only flexo press, a Uteco Crystal. The new arrival is giving the company a huge increase in capacity, but that was not the reason the company bought it. The investment was made due to the fact that some of the tenders the company was bidding for would only consider flexo.

Jimmy Urquhart, general manager said, ‘There are many misconceptions out there about gravure, some people think it costs a £1000 a cylinder, so if we wanted to go for these jobs we needed a flexo press, as talking about gravure just wasn’t happening.’

The company’s pedigree of printing quality meant that over time it had built up a customer base with some big household names in the UK market.

We want flexo!

Mr Urquhart explained, ‘It got to a point of pressure from some customers asking for flexo, which we haven’t used since 1986 when the company went completely gravure. We make our own gravure cylinders here in-house, so we are a little different to most gravure printers, as it means we can turn jobs around cheaper and quicker than our competitors. But even with explaining that, some customers still only want flexo.’

With jobs slipping out of their grasp, the company had to do something. Mr Urquhart continued, ‘I was sat in a service station with an old friend who had been telling me to get [a flexo press] for a long time, saying “You need to take a look at what we’re doing in flexo these days”. So we put the word out that we were in the market for a flexo press. Momentum was gathering quickly so we began to ask our customers whether they would support the business if some of their work was moved onto flexo, and they all said yes. The next thing you know we’ve spent a couple of million pounds on, not just a new press but, a whole new process. But with the reduced ink volumes and quick changeovers it’s hard to ignore.’

The company acheived what many others forget to do, the simple task of checking with their current client base whether they have a requirement for the new investment, rather than spending first and asking questions later.

The company’s client list includes a huge number of household names

Mr Urquart continued, ‘we put the pressure on Uteco and they have been excellent, we were saying if we can’t make this work then you guys will look bad too! They understood how important this was so were very supportive. They sent over an engineer to stay with us for about eight weeks to maker sure the team knew the machine.’

The company invested in a complement of Italian manufacturing, including a wide-web plate mounter from Camis, Rossini sleeves and plate storage rack, Grafikontrol web inspection, and Ferrarini & Benelli corona treatment units.

The transition itself was not too far of a leap for the team on the flexo press. They already knew print coming from gravure, so knew about registration, using films and colour management, so all they had to learn was the machine itself.

Help came in guise of other suppliers. Pre-press company Connect, a Schawk Group company based in Bury, was also on hand. Representatives accompanied Mr Urquhart and the team to Uteco’s facilities near Verona to look at the new press.

The press was shipped over in parts and then was assembled in the factory; a space which was previously used to stock substrates was cleared out to make room. The machine was assembled in three days, and then after a week or so of trials and test runs they were given clearence to start running jobs.

Trail of innovation

The investment is part of the company’s ethos to try to innovate and it works really hard to offer more for its customers, there is no interest to participate in a race to the bottom here.

This involves asking the customer what they want from their packaging, but this led to almost hundreds of different suggestions, too much to focus on. So in the end the team looked internally and asked themselves what they find frustrating with packaging. This approach has so far led to a number of different patent applications.

One such product was a new take on the carton drink and straw combination. As is common now, the straw is merely taped to the back or the side of the drink, if this detaches at any point before it reaches the customer, the packaging becomes obsolete in its original purpose of being a portable drink. With the Discovery Flexibles solution, the straw is kept inside the flexible packaging carton and is accessed by tearing off the corner of the packet.

Not only does this design eliminate waste due to unusable stock, but its flexible pouch design is of interest to airlines who think because of its flexible nature, makes it a more efficient way of storing drinks.

Another innovation came from the need to reduce supermarket fraud. The standard format of a microwave meal is a plastic tub covered with a carton sleeve. The sleeves have an inherent security flaw whereby they easily are interchangeable, allowing dishonest consumers to put a value ready meal cover over the tray of a premium food brand.

The company created a film flip lid attached to the container, this allows the consumer to lift the lid to see what the food looks like, allowing enough space for legislative information and cooking instructions, while also staying attached to the meal it was intended for.

Other innovative techniques have created sushi trays where the design on each tray is different. Customisation by any other name, however the process uses a flexo in-mould plastic. The design is printed and cut in a way that can make sure that no tray is the same as any other on the shelf, but each having a pattern similar enough to show they belong together.

There is a lot of interest in the improvement of hot ready meal packaging, especially the holy grail of the oven able printed container. This is another of the company’s patented technologies.

Brands want their packaging to be more and more colourful

Sustainability issues

A bigger project is on the horizon and has involved work with students from the local college and participation from one of the largest chicken farmers in the UK; active packaging and the ability to extend shelf life of almost all foodstuffs.

Mr Urquhart explained, We have been working with chicken suppliers to test film performance in the quest to enhance shelf life. We were told that if we could add one or two days to the shelf life of meat, it could be save millions for supermarkets and food suppliers. With the standard packaging we started with the meat’s shelf life was six days. With the new Discovery packaging it lasted an extra four days, giving it a total of 10 on the shelf.’

The packaging has been in development for the last 18 months, and has recently been approved by the EFSA (European Food Safety Authority), a major milestone in the production of new food packaging. It is now having trials for the shelf life of red meat, cheese and nuts. This product could help save millions of tonnes of food from going to waste every year, a severe problem for supermarkets around the world.

While this helps one major sustainability issue this packaging is still of course made of plastic, which has recently been highlighted as a problem for the industry, as the world’s oceans are on course to have more plastic in them than fish.

‘There is nothing inherently wrong with plastic if the recycling chain that’s in place can properly handle the volume of plastic and reuse it properly,’ said Mr Urquhart.

On demand flexo

Once the press was happily running, Mr Urquhart decided that it was time to show it off, to current and prospective customers, so organised a demo day with more than a little showmanship. Using visual and audio displays, complete with audience participation, Mr Urquhart showed the press off it every shape and form, but there was one demonstration which tested the nerves of his operators.

The demo was to show the possibilities and technological advances available right now that start to bridge the gap between flexo and digital. This was achieved by taking a different approach. At the demonstration Mr Urquhart asked the audience members to select a print option out of a hat. Upon doing that the option was immediately printed on press, at high speed, without the need to stop the press. It involved changing colours and data on the run at 500mpm. The team managed to change information on the run using less film than the height of the press. The crew then managed to change all 19 available options in less than half the length of the machine. This was flexo printing variably, and on demand, stealing a feather out of the digital printing cap.

Once again the company’s desire to innovate and push what is possible is shown, helping it to stand out in what is a very competitive market.

Mr Urquhart explained, ‘Using this machine now means that we are competing against some long term experienced flexo printers. Not having a background in flexo makes people nervous so we had to show customers that we know what we are doing, and go the extra mile.’

The flexo machine is hungry and had given the company a lot more capacity than it is used too. Mr Urquhart believes that it will not be long before the company’s jobs are split 50/50 between gravure and flexo, and that’s with one flexo press and three gravure presses. The press has brought with it 30 new jobs, 44 new customers and has increased turnover by 30%.

The installation is a real victory, not just for Discovery Flexibles but

for the entire flexo industry. At any flexo event the push for quality to rival and better gravure is always mentioned. Considered the poor cousin of gravure for many years, flexo has suffered with its public relations image, ‘potato printing’ is the term often thrown around, but here we have proof that flexo is more than a contender.