Print4All drew in over 30,000 visitors

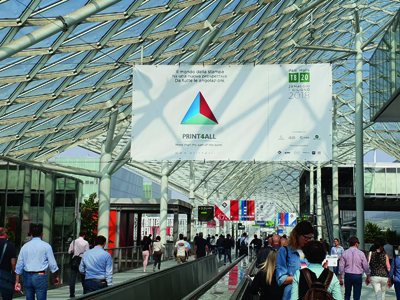

The first Print4All, part of a new trade show format created by ACIMGA, ARGI and Fiera Milano, opened its doors from 29 May-1 June and kept its promise to represent the entire printing industry. Michal Lodej reports.

The B2B trade show sector is a crowded market; especially in the printing industry. Print4All was always going to be compared to Converflex, the last iteration which was held in May 2015, but since then a lot has changed.

Getting the basics right is essential, and by simply ‘doing what it said on the tin’, Print4All ticked all the boxes by showing nearly every type of printing process going. As you would expect, the show certainly contained a lot more digital printing technology, and was full to the brim with digital OEMs that served not only the labels and packaging market but the commercial market too, including mailing and textile printing equipment.

Official numbers reported that Pritn4All drew over 30,000 visitors, while together with Ipack-Ima, Meat-Tech, Plast and Intralogistica Italia, the Innovation Alliance reports the total number of attendees as 150,000.

Familiar faces

The show featured many companies well known within the flexo market. IST was showing its Hot Swap module technology which allows users to switch from standard UV curing to UV LED curing. The latest generation of the software which comes with the unit, recognises which curing unit is in the press and communicates with the operator via a display to allow them to adjust the parameters needed for a full cure in production.

Eurograv was showing a wide range of Camis equipment including the Demounter, fully automatic LMA, Irisleeve 4.0 and the Demounter DMTS. With the event being so close to the company’s factory, Camis used the show to hold an agents meeting, and brought together agents from across the world to see where and how its products were made.

Anthony Foley, US agent, said, ‘International agents like myself got a tour of the new factory and a look at new developments on the horizon. We were shown new production efficiencies and got to see the machines being built in large sets rather than one at a time as this new facility is triple the size of the old place. Sante [FTA Europe president] also came and gave us a talk on the state of the industry, so it was a very useful trip.’

Merging in Milan

Goebel IMS used the show to announce its merger with Laem Systems. Kerstin Stumpf-Trautmann, group marketing manager, said, ‘Laem is a specialist in tooling in the primary and secondary converting so now together our resources are bundled together so now we can offer a wider range of products. There are no overlaps an there is nothing in the portfolio that doesn’t need to be there.’

Speaking of another merger, tesa and Twinlock were exhibiting at a show for the first time since they announced theirs.

Tom Watson, tesa, said, ‘The merger for us has always to be able to provide more solutions , and now with this adhesive sleeve all our customers can come to one source regardless of what they want to do. The merger has enabled us to complete, assortment to our customers and expand our business. It will continue to help us to grow and it has been very well received by our customers.’

KBA was able to tell FlexoTech that Peter Lechner will be joining the company to become managing director. Dr Lechner previously worked at Soma, where he was responsible for many of the company’s technical advancements.

On the booth, KBA was integrating the latest technology into its servicing and customer support procedures with the DataGlass.

The DataGlass is a virtual reality/augmented reality experience to allow the printer to be walked through any servicing or repairing on the machine. It will help them show how to fix any problems from mechanical faults to printing issues.

The device will help the company to provide a proactive service for customers, and has made parts ordering easier as well through the customer portal where users are simply able to book online. As it is browser based solution it can be accessed anywhere in the world and it also allows support help from other KBA technology users, not just from the company’s servicing team.

Meech’s Hyperion SmartControl provides remote static control adjustment

Commanding voice

The DataGlass is a voice controlled head set complete with monocle screen and a camera. The headset can connect the user to a service support with just three simple voice commands. Each user has their own individual login, in the form of a QR code which is simply scanned using the headset’s camera. This QR code contains the entire user’s information, so the support team knows whether they are speaking to a mechanic, electrician or a press operator.

Once logged in the support technician is able to see exactly what the user is seeing and can help make a diagnosis. If the fault can be fixed by the user there and then, the support technician can show where, how and what to do on the user’s screen and can walk them through it as it happens.

Once the technician has been shown how to rectify the problem and the press is back up and running, the session is logged by the data glass and is sent to them in an email from the support team, so that if the problem should arise again they can quickly see how the resolved it last time.

The system forces the support team to write a report of what happened. This system takes a lot of the stress and time out of technical support.

A blast from Plast

Print4All was of course co-located with a number of different shows, all connected with each other in some part of the packaging supply chain. One of these shows was Plast 2018 where many print related companies could be found.

Vetaphone had a good show which it said was an important event for company but from a slightly different angle for the corona treatment providers. The Italian market is an important one for the Danish company especially with the various OEMs in the region, and has been working hard to establish relationships with Italian machinery manufacturers. Speaking on behalf of Vetaphone, Nick Coombes said, ‘Our share of the market in narrow web printing is almost entirely ours. Now we have to look at wide web and for the coating equipment market and here the strategy is to align ourselves with the OEMs, but it’s a difficult one to tackle.’

Meech International used the show to launch the Hyperion SmartControl, a brand new remote monitoring and performance adjusting controller for the company’s popular range of Hyperion anti-static bars.

‘Plast provides the perfect platform for Meech to highlight its applications for the plastics industry,’ explained Adam Battrick, sales director at Meech International. ‘By displaying our varied and flexible range of ionising and surface cleaning systems, we are giving visitors and potential customers an insight into the importance of tackling static control and cleanliness issues which appear in plastic applications.’

Meech’s Hyperion SmartControl offers ease of communication between connected devices through LAN or WAN networks, allowing for continuous observation and alteration to static bar performance. The control system, which has been designed for use with Meech’s Hyperion static control equipment, allows for quick remote adjustment through a single interface, reducing the need for onsite monitoring.

‘Using the Hyperion SmartControl, operators of Hyperion static control equipment can access their static bar performance information on a remote device and adjust the operating settings to achieve maximum productivity and quality output’ said Mr Battrick.